Powder coating is a versatile and widely used finishing technique in various industries. This article aims to provide a detailed overview of what powder coating is and how it works. Whether you’re a DIY enthusiast or a professional in the field, understanding the principles and benefits of powder coating can be valuable. Let’s dive into the world of powder coating and explore its applications, processes, and advantages.

What is Powder Coating?

Defining Powder Coating

Powder coating is a dry finishing process used to apply a protective and decorative layer to various surfaces, primarily metal but also plastics and ceramics. Unlike traditional liquid paint, powder coating uses finely ground particles of pigment and resin, which are electrostatically charged and sprayed onto the object to be coated.

History of Powder Coating

The concept of powder coating dates back to the 1940s when it was initially developed as an alternative to liquid paint. Its commercial use began in the 1960s, and since then, it has evolved into a mainstream finishing method for countless products.

Importance in Modern Manufacturing

Today, powder coating plays a vital role in modern manufacturing, offering superior performance, durability, and environmental advantages. It has become the preferred choice for industries ranging from automotive and aerospace to architectural design and household appliances.

How Does Powder Coating Work?

Powder Coating Ingredients

Powder coatings consist of three main components: resin, pigment, and additives. The resin serves as the binder that holds the powder together when it’s applied and then melts during the curing process. Pigments give the powder its color, and additives enhance various properties like flow, UV resistance, and texture. You can also read Painting Services In Pittsburgh

The Application Process

The application of powder coating involves several key steps:

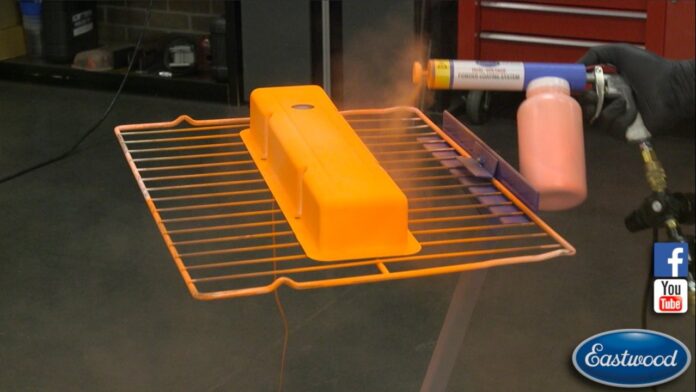

- Surface Preparation: Before coating, the surface must be thoroughly cleaned and pre-treated to remove any contaminants and ensure proper adhesion.

- Powder Application: The powder is electrostatically charged in the spray gun, creating a strong attraction to the grounded workpiece. This results in an even and uniform distribution of the powder.

- Curing: The coated object is then heated in an oven, causing the powder to melt and form a continuous film. This process is called curing and typically occurs at temperatures between 300 to 450 degrees Fahrenheit.

Curing and Final Finish

During curing, the melted powder chemically crosslinks to create a robust, durable, and attractive finish. Once cooled, the coated object is ready for use. The final finish can vary from a glossy or matte appearance to textures like wrinkles or metallic effects, depending on the type of powder used.

Types of Powder Coatings

Thermosetting vs. Thermoplastic Powders

Powder coatings are broadly categorized into two main types: thermosetting and thermoplastic powders.

- Thermosetting Powders: These powders chemically react during curing, forming a solid, irreversible bond. They are known for their exceptional durability and are commonly used in outdoor applications.

- Thermoplastic Powders: Unlike thermosetting powders, these coatings can be reheated and remelted, making them more flexible and easier to rework. They are often used for functional coatings.

Specialty Powder Coatings

Specialty powder coatings include unique formulations designed for specific purposes, such as anti-graffiti, anti-bacterial, or heat-resistant coatings. These coatings offer enhanced performance characteristics to meet specialized requirements.

Choosing the Right Powder Coating

Selecting the appropriate powder coating depends on factors like the intended application, environmental conditions, and desired finish. Manufacturers often provide a wide range of color options and formulations to cater to diverse needs.

Advantages of Powder Coating

Durability and Longevity

Powder coatings are renowned for their durability and longevity. They resist chipping, fading, and corrosion, making them ideal for items exposed to harsh environmental conditions or high wear and tear.

Environmental Benefits

Powder coating is an environmentally friendly finishing method. Unlike liquid paints, it produces minimal volatile organic compounds (VOCs) and does not require solvents. This reduces air pollution and contributes to a cleaner and safer environment.

Aesthetic Versatility

Powder coatings offer a wide range of colors, textures, and finishes, allowing for endless design possibilities. Whether you need a glossy, matte, or textured finish, powder coating can deliver.

Cost-Efficiency

While the initial setup for powder coating may be more expensive than traditional painting methods, its long-term benefits far outweigh the costs. The reduced need for touch-ups, repainting, and maintenance make it a cost-effective choice in the long run.

Applications of Powder Coating

Automotive Industry

Powder coating is extensively used in the automotive industry for coating components like wheels, frames, and chassis. Its durability and resistance to road debris and weather conditions make it an excellent choice.

Furniture and Home Decor

From outdoor furniture to appliances, powder coating is a popular choice for adding both aesthetics and protection to various household items. It can withstand exposure to sunlight, moisture, and everyday wear.

Industrial Equipment

Machinery, tools, and industrial equipment benefit from powder coating’s protective qualities. It prevents rust and corrosion, ensuring the longevity and performance of these vital assets.

Architectural Uses

Powder coating is also employed in architectural applications, such as coating aluminum extrusions for windows, doors, and curtain walls. Its resistance to fading and weathering ensures the building’s aesthetic appeal over time.

Common Challenges and Troubleshooting

Overcoming Common Issues

While powder coating is a reliable finishing method, challenges like uneven coating, orange peel texture, or poor adhesion can occur. These issues can often be resolved through proper surface preparation, gun adjustment, and curing temperature control.

Maintenance and Care

Powder-coated surfaces are relatively low-maintenance. Regular cleaning with mild soap and water can help preserve their appearance and extend their lifespan.

Conclusion

In conclusion, powder coating is a versatile and environmentally friendly finishing technique that offers numerous advantages in terms of durability, aesthetics, and cost-efficiency. Whether you’re a manufacturer looking to enhance your products or a homeowner seeking long-lasting protection for your possessions, powder coating is a compelling choice. Understanding its processes and benefits can empower you to make informed decisions about your coating needs. So, the next time you admire the flawless finish on a metal or plastic object, remember that powder coating likely played a crucial role in achieving that result.